- Home

-

Projectors

-

E-Vision Projectors

Premium 1-Chip DLP • 3,800 - 15,000 Lumens

-

E-Vision Laser 15000 WU

- WUXGA Resolution

- 15000 lumens

-

E-Vision Laser 13000 WU

- WUXGA Resolution

- 13500 lumens

-

E-Vision Laser 11000 4K-UHD

- 4K-UHD Resolution

- 10500 lumens

-

E-Vision Laser 10K

- WUXGA Resolution

- 11250 lumens

-

E-Vision 10000i WU

- WUXGA Resolution

- 9600 lumens

-

E-Vision 9100

- WUXGA Resolution

- 8600 lumens

-

E-Vision Laser 9000 WU

- WUXGA Resolution

- 9000 lumens

-

E-Vision Laser 8500

- WUXGA Resolution

- 8500 lumens

-

E-Vision 8000i WU

- WUXGA Resolution

- 7600 lumens

-

E-Vision Laser 4K-UHD

- 4K-UHD Resolution

- 7500 lumens

-

E-Vision 7010-WU

- WUXGA Resolution

- 7000 lumens

-

E-Vision Laser 6500 II

- WUXGA Resolution

- 6500 lumens

-

E-Vision 6110-WU

- WUXGA Resolution

- 6100 lumens

-

E-Vision LASER 5900 WUXGA

- WUXGA Resolution

- 6000 lumens

-

-

M-Vision Projectors

Premium 1-Chip DLP • 18,000 - 23,000 Lumens

-

M-Vision 27000 WU

- WUXGA Resolution

- 27000 lumens

-

M-Vision 24000 WU

- WUXGA Resolution

- 24000 lumens

-

M-Vision Laser 21000 WU

- WUXGA Resolution

- 21000 lumens

-

M-Vision Laser 18K

- WUXGA Resolution

- 18000 lumens

-

-

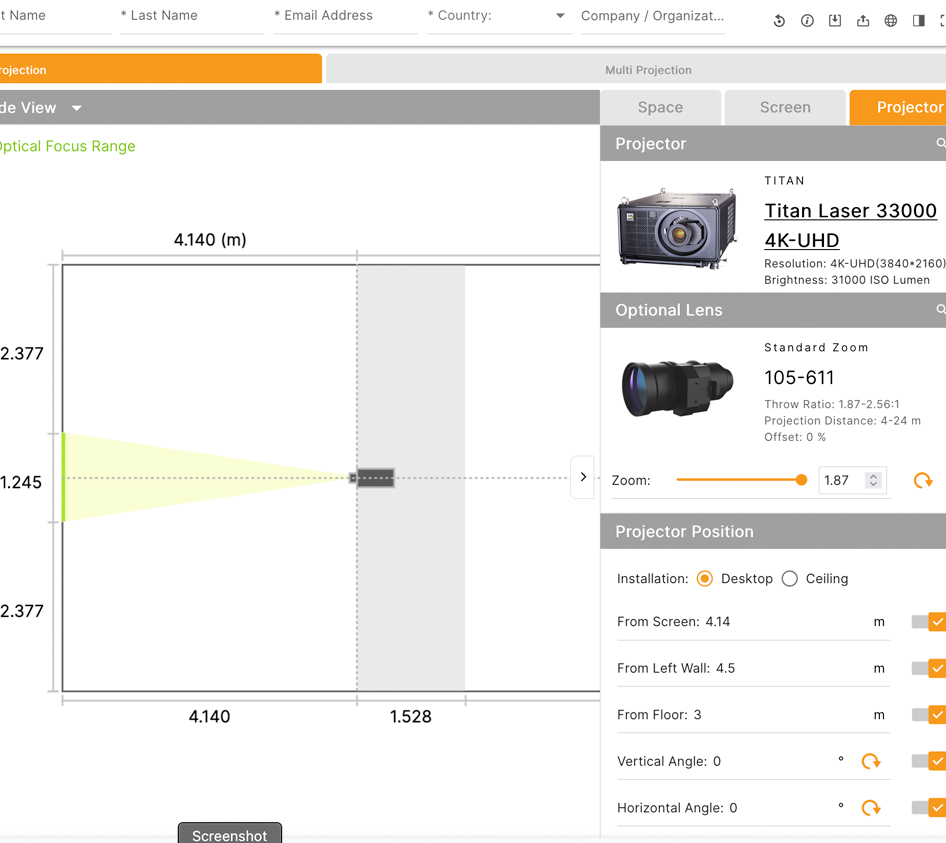

TITAN Projectors

Premium 3-Chip DLP • 26,000 - 37,000 Lumens

-

TITAN Laser 47000 WUXGA / 41000 4K-UHD

- WUXGA Resolution

- 47000 lumens

-

TITAN Laser WUXGA / 4K-UHD

- WUXGA Resolution

- 37000 lumens

-

-

INSIGHT Projectors

8K Resolution • Up to 37,000 Lumens

-

INSIGHT LASER 8K (Gen I)

- 8K Resolution

- 25000 lumens

-

INSIGHT LASER 8K (Gen II)

- 8K Resolution

- 37000 lumens

-

-

Satellite MLS Projectors

Modular Laser System • 20,000 - 40,000 Lumens

-

Satellite Modular Laser System (MLS)

- WUXGA Resolution

- 23000 lumens

-

-

E-Vision Projectors

Premium 1-Chip DLP • 3,800 - 15,000 Lumens

-

LED Displays

-

Performance Series LED

Peak LED Performance • Up to 1,500 Nits

Performance Series LED

Peak LED Performance • Up to 1,500 Nits

-

VX Series Radiance LED

Exceptional Performance Value • Up to 600 Nits

VX Series Radiance LED

Exceptional Performance Value • Up to 600 Nits

-

RCS Series Radiance LED

Reconfigurable LED Displays • Up to 2,500 nits

RCS Series Radiance LED

Reconfigurable LED Displays • Up to 2,500 nits

-

Outdoor Series Radiance LED

All Weather displays • Up to 10,000 nits

Outdoor Series Radiance LED

All Weather displays • Up to 10,000 nits

-

Studio Series Radiance LED

Engineered for Virtual Production & XR • Up to 1,500 nits

Studio Series Radiance LED

Engineered for Virtual Production & XR • Up to 1,500 nits

-

EV Series Radiance Micro LED

Peak LED Brightness • Up to 1,200 nits

EV Series Radiance Micro LED

Peak LED Brightness • Up to 1,200 nits

-

LED Resources

For Truly Stunning LED Viewing Experiences

LED Resources

For Truly Stunning LED Viewing Experiences

-

-

Markets

- Pro AV Precision projectors for your most demanding Pro AV installations

- Residential Entertainment Experience Residential Entertainment the way Hollywood intended

- Houses of Worship Powerful inspiration for your congregation

- Higher Education Powerful displays that help your lectures pack a punch

- Projection Mapping Creating breath-taking images and experiences that that captivate your audience

- Simulation & Training Simulation & training for any environment

- Visualization and VR Truly immersive, collaborative and interactive 3D experiences

- Case Studies

-

Contact Us

- Home

-

Projectors

-

E-Vision Projectors

Premium 1-Chip DLP • 3,800 - 15,000 Lumens

-

E-Vision Laser 15000 WU

- WUXGA Resolution

- 15000 lumens

-

E-Vision Laser 13000 WU

- WUXGA Resolution

- 13500 lumens

-

E-Vision Laser 11000 4K-UHD

- 4K-UHD Resolution

- 10500 lumens

-

E-Vision Laser 10K

- WUXGA Resolution

- 11250 lumens

-

E-Vision 10000i WU

- WUXGA Resolution

- 9600 lumens

-

E-Vision 9100

- WUXGA Resolution

- 8600 lumens

-

E-Vision Laser 9000 WU

- WUXGA Resolution

- 9000 lumens

-

E-Vision Laser 8500

- WUXGA Resolution

- 8500 lumens

-

E-Vision 8000i WU

- WUXGA Resolution

- 7600 lumens

-

E-Vision Laser 4K-UHD

- 4K-UHD Resolution

- 7500 lumens

-

E-Vision 7010-WU

- WUXGA Resolution

- 7000 lumens

-

E-Vision Laser 6500 II

- WUXGA Resolution

- 6500 lumens

-

E-Vision 6110-WU

- WUXGA Resolution

- 6100 lumens

-

E-Vision LASER 5900 WUXGA

- WUXGA Resolution

- 6000 lumens

- > View all E-Vision Projectors

-

-

M-Vision Projectors

Premium 1-Chip DLP • 18,000 - 23,000 Lumens

-

M-Vision 27000 WU

- WUXGA Resolution

- 27000 lumens

-

M-Vision 24000 WU

- WUXGA Resolution

- 24000 lumens

-

M-Vision Laser 21000 WU

- WUXGA Resolution

- 21000 lumens

-

M-Vision Laser 18K

- WUXGA Resolution

- 18000 lumens

- > View all M-Vision Projectors

-

-

TITAN Projectors

Premium 3-Chip DLP • 26,000 - 37,000 Lumens

-

TITAN Laser 47000 WUXGA / 41000 4K-UHD

- WUXGA Resolution

- 47000 lumens

-

TITAN Laser WUXGA / 4K-UHD

- WUXGA Resolution

- 37000 lumens

- > View all TITAN Projectors

-

-

INSIGHT Projectors

8K Resolution • Up to 37,000 Lumens

-

INSIGHT LASER 8K (Gen I)

- 8K Resolution

- 25000 lumens

-

INSIGHT LASER 8K (Gen II)

- 8K Resolution

- 37000 lumens

- > View all INSIGHT Projectors

-

-

Satellite MLS Projectors

Modular Laser System • 20,000 - 40,000 Lumens

-

Satellite Modular Laser System (MLS)

- WUXGA Resolution

- 23000 lumens

- > View all Satellite MLS Projectors

-

-

E-Vision Projectors

Premium 1-Chip DLP • 3,800 - 15,000 Lumens

-

LED Displays

-

Performance Series LED

Peak LED Performance • Up to 1,500 Nits

Performance Series LED

Peak LED Performance • Up to 1,500 Nits

-

VX Series Radiance LED

Exceptional Performance Value • Up to 600 Nits

VX Series Radiance LED

Exceptional Performance Value • Up to 600 Nits

-

RCS Series Radiance LED

Reconfigurable LED Displays • Up to 2,500 nits

RCS Series Radiance LED

Reconfigurable LED Displays • Up to 2,500 nits

-

Outdoor Series Radiance LED

All Weather displays • Up to 10,000 nits

Outdoor Series Radiance LED

All Weather displays • Up to 10,000 nits

-

Studio Series Radiance LED

Engineered for Virtual Production & XR • Up to 1,500 nits

Studio Series Radiance LED

Engineered for Virtual Production & XR • Up to 1,500 nits

-

EV Series Radiance Micro LED

Peak LED Brightness • Up to 1,200 nits

EV Series Radiance Micro LED

Peak LED Brightness • Up to 1,200 nits

-

LED Resources

For Truly Stunning LED Viewing Experiences

LED Resources

For Truly Stunning LED Viewing Experiences

-

-

Markets

- Pro AV Precision projectors for your most demanding Pro AV installations

- Residential Entertainment Experience Residential Entertainment the way Hollywood intended

- Houses of Worship Powerful inspiration for your congregation

- Higher Education Powerful displays that help your lectures pack a punch

- Projection Mapping Creating breath-taking images and experiences that that captivate your audience

- Simulation & Training Simulation & training for any environment

- Visualization and VR Truly immersive, collaborative and interactive 3D experiences

- Case Studies

- Contact Us